Analytical Instrumentation

Safe and Accurate Analysis of Sulfur Compounds in LPG by GC-LGI-FPD

Nov 18 2015

Several GC methods are available to quantify individual sulfur compounds in LPG that require a sample introduction into a GC inlet via a gas/liquid sampling valve. To allow a direct injection of the LPG in a GC inlet Da Vinci Laboratory Solutions developed the Liquefied Gas Injector (LGI).

The LGI is a closed system for the direct injection of liquefied petroleum gases into the GC inlet. This avoids any contact of the sample with transfer lines, vaporisers or valves and ensures a good sample transfer into the heated zone of the inlet.

Proven Technology

In 2010 Da Vinci developed the direct, on-column LPG injection technique based on a proven system used by the automotive industry to inject fuel into the automotive engine combustion chamber. The LGI was originally applied for the analysis of oily residue in LPG and has been approved as ASTM D7756 and EN 16423.

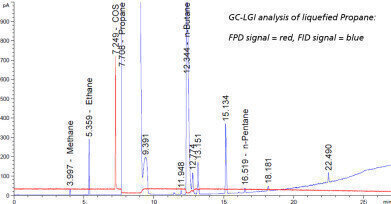

The GC-LGI solution includes the Liquefied Gas Injector (LGI) configured on top of a GC together with a controller box. A pressure station injects the pressurised gas as a liquid directly onto the GC column by keeping the pressure at a constant level of 25 bar. This results in a representative sample injection of the LPG sample. For the quantification of the sulfur compounds a sulfur specific Flame Photometric Detector (FPD) is used.

Sulfur Compounds in C3, C4 and C5 Streams

A new application note describes the use of the LGI-GC technique for the analysis of sulfur compounds in liquefied Propane and Butane samples and in a liquid Pentane sample.

Using a PFD detector the limits of quantification (LOQs) range from 0.18 to 0.27 mg sulfur/kg and the limits of detection (LODs) from 0.05 to 0.08 mg sulfur/kg respectively. This demonstrates that the LGI-GC technique combined with a sulfur specific detector offers a powerful tool for sulfur control of liquefied petroleum gas samples and liquid pentane samples.

The DVLS Liquefied Gas Injector offers the petrochemical industry numerous benefits:

-

Innovative sampling technique - A high pressure injection valve connected to an injection needle ensures a direct on-column LPG injection.

-

High safety - The direct injection approach of the LGI eliminates the need for sample evaporation of the LPG.

-

Representative sample injection – The Pressure Station allows to inject a representative sample of the pressurised gas as a liquid.

-

Wide application range:

-

Oily residues and light contaminants in LPG (ASTM D7756, EN 16423)

-

Hydrocarbon composition of LPG (ASTM D 2163, ISO 7941)

-

Sulfur compounds in liquefied petroleum gases

-

Desulfurization additives in LPG: DIPA, MEA & DEA

-

Inhibitors, additives and Dimers in Butadiene: ACN, ρTBC, Butadiene Dimer

-

N2, CO2, H2S and Hydrocarbons in Unstabilised Gas Condensate

-

-

Fast analysis time of less than 30 minutes.

Download the application notes for a complete description of the various analyses performed with the DVLS Liquefied Gas Injector.

Digital Edition

PIN 25.2 Apr/May

May 2024

Safety - Carbon monoxide toxic and flammable gas detection Analytical Instrumentation - Density: A fundamental parameter at critical stages within the petroleum sector - Advancements and...

View all digital editions

Events

May 18 2024 Rio de Janeiro, Brazil

May 19 2024 Minneapolis, MN

May 20 2024 Columbus, OH, USA

May 20 2024 Dubai, United Arab Emirates

May 23 2024 Beijing, China