-

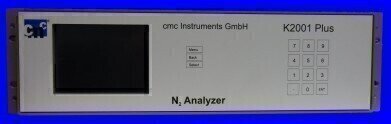

K2001+ Trace Nitrogen Analyser

K2001+ Trace Nitrogen Analyser

Analytical Instrumentation

New Trace Nitrogen Analyser

Nov 14 2012

The new K2001 Plus Trace Nitrogen Analyser from cmc Instruments is just as at home in the laboratory or on the plant. The rugged, maintenance free design combined with state of the art electronics to give high performance, ppm measurements over many years.

Argon purification, helium liquefaction and air separation plants are major applications. These plants rely on trace nitrogen measurement to establish the purity of their production. The techniques used to manufacture and purify these gases mean that any remaining impurity at the ppm level will largely be nitrogen. Trace nitrogen analysis enables the purity of the gas to be confirmed. The semiconductor industry also uses ultra high purity inert gases which require purity verification.

The K2001 Plus is designed specifically for ultra pure argon or helium gas applications. Plasma Emission Detector technology uses a Duty Cycle Controlled system to deliver high performance. Online ppb nitrogen measurement is now possible without resorting to a gas chromatograph, and it's maintenance free.

The unique design decreases contamination in the plasma cell extending the lifetime, improving reliability and increasing accuracy. A clever micro-valve delivers minimal dead volume and a fast purge time. Touch screen, Ethernet software updates, choice of serial communications including Profibus and a convenient 3U rack mount design makes it an attractive package for industry and laboratory.

cmc Instruments have been supplying German customers with the best in trace gas measurement solutions for many years, now this new development is available throughout Europe. The K2001 Plus represents the latest addition in a long line of analysers. Sales engineers at cmc Instruments are waiting to offer you the best solution for all your trace gas measurement applications.

cmc Instruments also manufacture trace moisture analysers, gas generators, filter systems for process gases (including chlorine) and the new WearSens® and OilQSens® - patented, online system for early detection of oil quality deterioration in roller bearings, gears and transformers.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia